|

|

| LSE Vari EZE

|

Jon

Johanson's RV |

LIGHT SPEED ENGINEERING'S

ELECTRONIC IGNITION SYSTEMS

Light

Speed Engineering, LLC (LSE)

is a pioneer in the design and production of ignition systems for

experimental aircraft.

Nineteen years of research and development have been invested

in producing the PLASMA CDI (Capacitive Discharge Ignition) system

product line.

LSE's PLASMA CD systems are the ideal replacement for yesterday's

magneto technology. You can replace one mag with a PLASMA CDI

or, for maximum performance, replace both magnetos with these state

of the art systems.

The Plasma

CDI is a solid-state, high performance ignition system intended for

today's home

built aircraft. Light Speed Engineering currently offers two Capacitive Discharge Ignition Systems:

the PLASMA II PLUS and the PLASMA III. They

are available for Lycoming, Continental, Franklin,

and other aircraft engines with even number

cylinders.

Standard

Plasma CDI kits include: triggering mechanism (DCmini

Sensor or Hall Effect Module only available for

4-cyl. engines ), high tension leads, harness, spark

plugs, spark plug adapters, and ignition coils

with mounting bracket. One or two systems can be used.

Accessory

case driven Hall Effect Sensor Module available

for all 4-cyl Lycoming and Lycoming type

(i.e. Superior, ECI...) engines.

Custom timing curve on all Turbo and Super-Charged ignition systems,

add $125 per ignition system.

Laser cut mounting bracket, magnet holder and

counter-weight on Continental engine ignition

systems, add $195 per engine installation.

Optional RPM Limiter feature available for Plasma

III systems, add $275.

The

following capabilities and output features are

included on all

Plasma II Plus and Plasma

III ignition systems:

| *Key Start

Option- Allows the use of aircraft key switch |

| *Output 1-

Timing Advance |

| *Output 2-

Manifold Pressure |

| *Output 3-

RPM |

| *Output 4-

(+)5V Power for the optional LCD Display |

| *Cockpit

adjustable timing advance |

| *Interconnect-

for Dual PLASMA CDI |

PLASMA II

PLUS

The

PLASMA II Plus is Light Speed Engineering's basic

electronic ignition system for aircraft. It

is a lightweight, high-energy capacitor discharge

system containing all of the essential Plasma CDI

features. Its smaller size and lighter

weight sets it apart from any other ignition

source.

Like

all LSE ignition systems, it features automatic

ignition advance based on engine load and RPM,

auto retard for starting, and a standard pulse tachometer output.

--------------------------------------------

PLASMA III

The

PLASMA III is Light Speed Engineering's high

performance continuous spark capacitor discharge

ignition system. The Plasma III has a dual

output stage which allows the spark to oscillate back and forth for

a minimum of 20 degrees crankshaft rotation. This long

duration spark allows further leaning without lean

misfiring for added fuel efficiency it also noticeably increases horsepower

output and engine smoothness.

The PLASMA II PLUS and the PLASMA III have the output capabilities listed above

(click here) and they are pin compatible.

Timing advance, manifold pressure, and RPM information can be

read in the cockpit using Light Speed Engineering's pre-wired

digital display- option available with PLASMA II PLUS and PLASMA III

systems. (Not included with systems.) Follow this

link for more information on the pre-wired display: Digital

Display.

All

Light Speed Engineering ignition systems have automatic spark retard

for starting. This allows both magnetos to be replaced with

two PLASMA CDI systems.

PLASMA CDI TRIGGERING

MECHANISMS

Light

Speed Engineering is building on the proven

performance of the Direct Crank Sensor design for

the new DC Mini Sensor. It uses the same

Hall Effect Sensor technology we have used with

great success for the past 14 years but is

smaller, lighter and more robust integrated

package.

Additional

information can be found on the Mini

Sensor page.

Available

by special request only:

DIRECT

CRANK SENSOR.

This has been

superceded by the Mini Sensor. |

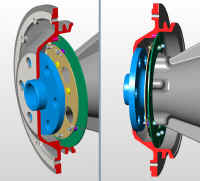

The direct crank sensor system provides complete redundancy

for single or dual Plasma CDI systems. This

crank sensor concept requires removal of the

flywheel for installation. Integrated

magnets in the flywheel are used to trigger miniature hall effect

sensors mounted on LSE's proprietary circuit board. This

sensor board is mounted to the crankcase via custom brackets for

Continental and Lycoming engines. The direct crank sensor system provides complete redundancy

for single or dual Plasma CDI systems. This

crank sensor concept requires removal of the

flywheel for installation. Integrated

magnets in the flywheel are used to trigger miniature hall effect

sensors mounted on LSE's proprietary circuit board. This

sensor board is mounted to the crankcase via custom brackets for

Continental and Lycoming engines.

6-cyl engines and engines

equipped for single drive dual magnetos use

the direct crank sensor assembly or the DCmini Sensor assembly.

Further

information on the direct crank sensor triggering mechanism may be

found on the Crank Sensor page.

ACCESSORY

CASE HALL EFFECT SENSOR MODULE

(4-CYL. LYCOMING &

LYCOMING TYPE) |

Light

Speed Engineering,

LLC's Plasma Capacitive Discharge

Ignition systems employ the latest hall sensor

technology to provide maximum reliability and easy

installation on Lycoming

engines.

The Hall Effect Sensor Module is installed

in place of the magneto and driven by the gear

from a non-impulse magneto.

A built in timing light makes the

installation easy and reliable.

The primary benefit of this triggering device is its straight

forward installation. Simply fit the module with a

non-impulse drive gear and mount it in your empty mag hole-- effectively

plug and play.

4-cyl Lycoming engines are capable of using either the

Hall Effect Module mounted in place of the magneto

or the direct crank sensor

assembly for crankshaft position information. This accessory

case mounted Hall Effect Module replaces single magnetos on Lycoming

(or Lycoming- type) engines.

Two

modules can be used to provide full trigger

redundancy with dual electronic ignition

installations.

* Non-impulse drive gears not included.

|