|

Available by special request

only:

DIRECT

CRANK

SENSOR SYSTEM

- This triggering method

has been superceded by the Mini Sensor

system.

Light

Speed Engineering, LLC has developed three different devices to send

crankshaft position information to the Plasma CD ignition

systems. One method uses the Hall Effect Module which is

installed in the accessory case and senses crank shaft position by

means of the non-impulse magneto drive gear. The second mechanism is the Mini Sensor described on the Mini

Sensor page located here. The old

style triggering mechanism is

the Direct Crank Sensor system described here.

The

Direct Crank Sensor triggering mechanism is versatile and will work

with most aircraft engines.

All 6-cylinder

engines and all Continental engines must use the Direct Crank Sensor

or the Mini Sensor.

The

crank sensor circuit board has two completely independent triggering

circuits if it is used for dual Plasma CDI applications.

On single installations only the outer set of sensors and

associated wiring harness is installed.

Lycoming Direct Crank Sensor Installation

Lycoming

Narrow-Deck Direct Crank Sensor Installation

Continental 6-cyl

Crank Sensor Installation

Also

applicable for Franklin 6-cyl. engines.

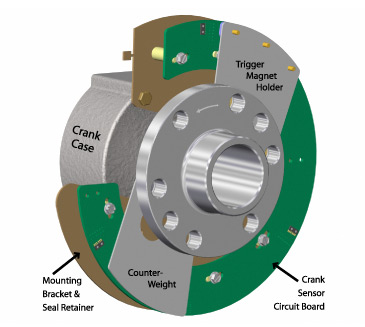

Pictured

above are the trigger magnet holder, counter weight, and crank sensor mounting bracket

designed specifically for Continental 550 engines.

Add $195 to the ignition system price.

Continental

O-200 Crank Sensor Installation

The crank sensor

mounting bracket and trigger magnet plate designed

specifically for the Continental O-200 engine are

pictured below. Add $195 to the ignition

system price for installation on a Continental

engine.

|

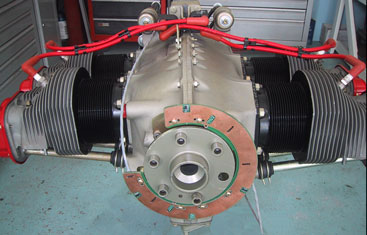

Crank

Sensor

Mounting

Bracket

Installed

|

|

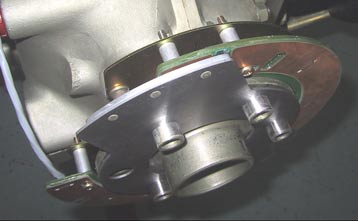

Direct Crank

Sensor

Board

Attached to

Crankcase

Mounting

Bracket |

|

Crank

Sensor

Board and

Trigger

Magnet

Bracket

Installed.

|

|